Right Technology Selection

Not sure about which process is the correct one for your part design?

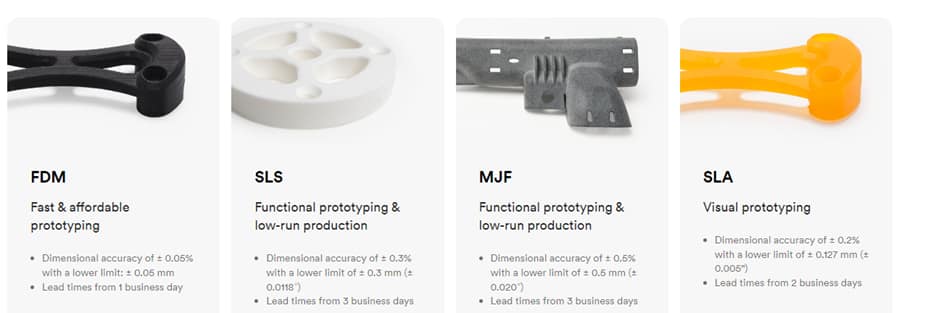

We understands the key benefits and limitations of each 3D printing process and how much it is important for you to have an overview of the fundamental mechanics of the right technology which matches your application. We at yugAI3d assist you in finding the right process for your designs and functional prototypes, by taking different key manufacturing criteria into account, such as:

- Dimensional stability – Processes that offer higher accuracy can usually create parts with finer features.

- Build size – Suggesting right technology, or finding a alternative for parts that exceed typical build size.

- Support structure – Process that required no support, having fewer limitations with more design freedom.

- Cost per part – Assisting you since beginning to choose among different technologies, for scope of series production of your parts.

Unlock various features of 3D Printing

- Multi Material 3D Printing – Using more than one type of material within single part, eliminating need for assembly, and promoting multipurpose part designs.

- Conductive filament – Inbuild electrical flow using conductive material, eliminating external need of wirings.

Material Selection Assistance

With our interactive material selection assistance, we will help you in choosing the right material for your use case.

- Low temperature polymers

- High Temperature polymers

- UV Radiant materials

- ESD Safe materials

- High strength plastic

- Bio compatible material

- Flame retardant material

- TPU 60 A Shore rubber material

- Chemical resistance

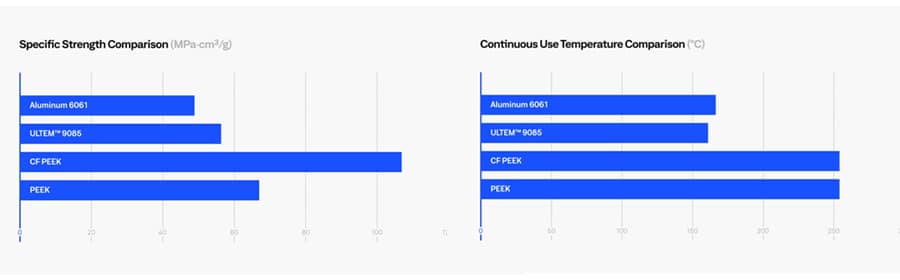

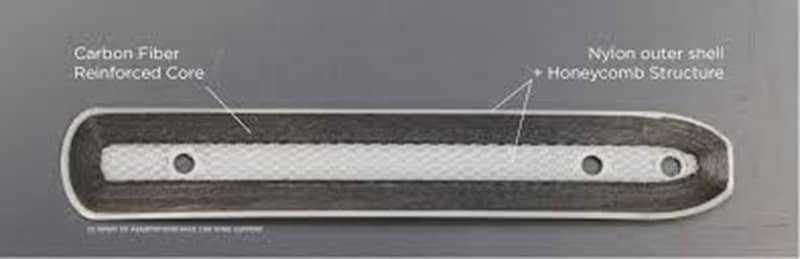

Strong and Light weight plastic printing.

- Stronger than normal plastic.

- Stronger and lighter than Aluminum plastic printing materials.

- Carbon Fiber reenforced Material printing

Get It 3D Printed

Yug3DAI makes sourcing custom parts easy and affordable. Provide us some info and we’ll do the rest!